Innovations

New innovative process from WAFO Klaus Wagner GmbH

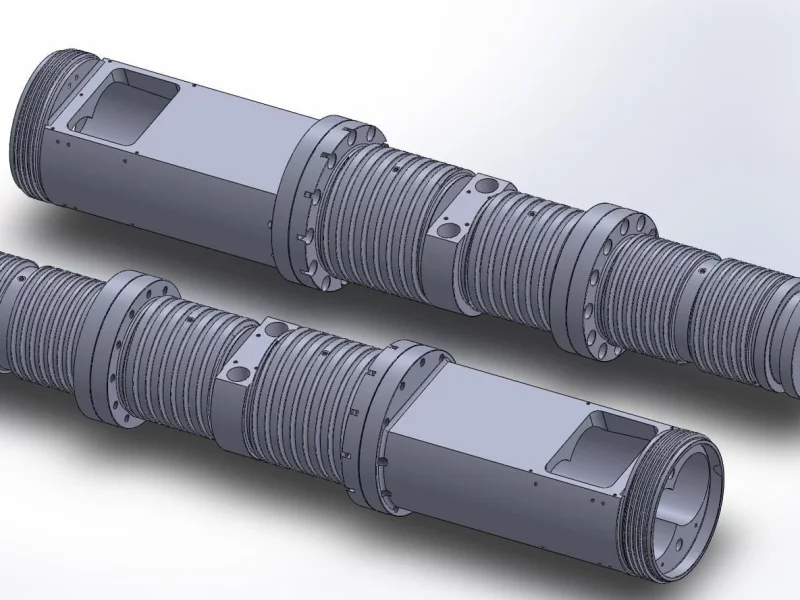

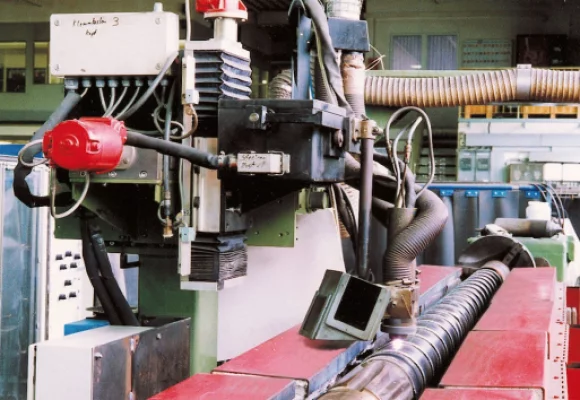

Internal coating of a conical twin-screw cylinder CM80 using the modified HVOF process with our highly wear-resistant alloy TC-86 (with a tungsten carbide content of 86%).

The process is suitable for all conical and parallel double cylinders.

Trade fairs / Dates

- Trade fair28. Fakuma - International Trade Fair for Plastics Processing

17 to 21 October 2023 | Messe Friedrichshafen

- Trade fairVIETNAM PLAS 2023 - International Trade Fair for the Plastics and Rubber Industry

18 to 21 October 2023 | Ho Chi Minh (Vietnam) | Saigon Exhibition & Convention Center - SECC